At a microscopic level, magnetic alloy powder grains are separated from one another by binder insulation or by high temperature insulation coating each grain. Distributed gap materials are powder cores.

The power inductor gap may be realized in one of two fashions, discrete or distributed. The physics of soft magnetic materials result in the case that commericially useful materials range from about 0.3T to 1.8T in Bsat. One envelope constraint is that Bsat is not widely variable. Since μ = B/H, the lower the value of μ, the greater the value of H (or current) that is supported at a level of B that is less than the maximum value of flux density (Bsat) inherent in the magnetic material.

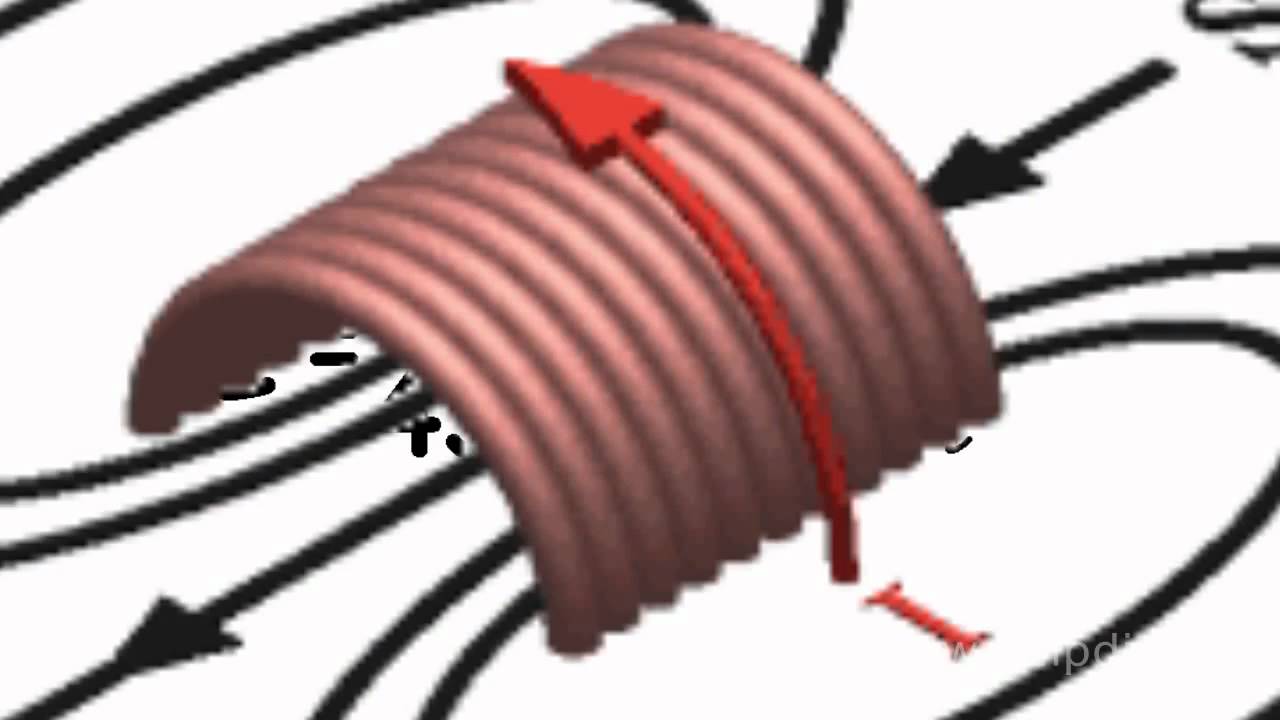

Another way to express the function of the air gap is to say that it reduces and controls the effective permeability of the magnetic structure. The purpose of the gap is to store the energy, and to prevent the core from saturating under load. Power inductors require the presence of an air gap within the core structure. By resisting change in current, the filter inductor essentially accumulates stored energy as an AC current crests each cycle, and releases that energy as it minimizes.

An inductor is a current filtering device.

0 kommentar(er)

0 kommentar(er)